Flash forward to last week and Peter Follansbee tells me that he is making some benches out of the oak flitches we had left over from some band sawing we had done for the "Big Fence" Project. I again thought nothing of what Peter had said...that was until I saw what the benches looked like.

Instantly I thought back to the spindly legged workbenches that Chris had written about with slab tops and holes for holdfasts and planing stops. The two forms, deriving from two seemingly opposite origins, shared a shockingly similar appearance, in fact, they were so similar that I almost grabbed a brace and bit, bored a couple of holes in Peters bench, and took it for a test spin.

Needless to say I did not actually go through with this plan, for starters Peter would not be too happy to have me putting holes in his benches, and secondly I need to do some hardcore research into 17th century work holding and whether or not the "Roman" form was still in use by agricultural societies...like English planters in New England...say around 1627. Off to the archives!

PS. I am pretty sure Chris and Peter are in cahoots. Kind of the ebb and flow of the hand tool world. They pretend as though they butt heads, but really they are masterminding the greatest renaissance since....well the renaissance. St. Roy probably has something to do with this as well.

|

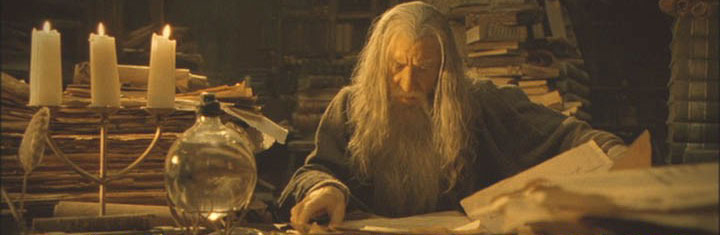

| Research will probably look something like this... |

PS. I am pretty sure Chris and Peter are in cahoots. Kind of the ebb and flow of the hand tool world. They pretend as though they butt heads, but really they are masterminding the greatest renaissance since....well the renaissance. St. Roy probably has something to do with this as well.